Published on: 02 Feb 2026

Mastering Industrial Embroidery: Choosing Needles, Threads, and Backing for Quality

Key takeaways for garment factories:

- Achieving high-quality industrial embroidery fundamentally relies on the intelligent selection of needles, threads, and backing materials, not just the machine itself.

- Matching the correct needle type and size to the fabric prevents damage, skipped stitches, and ensures smooth production.

- Selecting optimal thread material and count impacts the visual quality, durability, and operational efficiency of embroidery.

- Proper backing provides crucial stability, preventing puckering and distortion, and ensures a professional finish.

- Investing in premium consumables, despite higher initial cost, significantly reduces downtime, rework, and material waste, leading to higher output, better quality, and ultimately, increased profit margins.

Table of Contents

- Understanding the Embroidery Ecosystem: Needles, Threads, and Backing

- Where and Why These Choices Matter: A Garment Factory’s Perspective

- Technical Aspects of Industrial Embroidery

- The True Cost of Consumables: Initial Price vs. Operational Efficiency

- Troubleshooting Common Embroidery Issues

- Selection Checklist for Garment Factories

- Key Takeaways

- Frequently Asked Questions

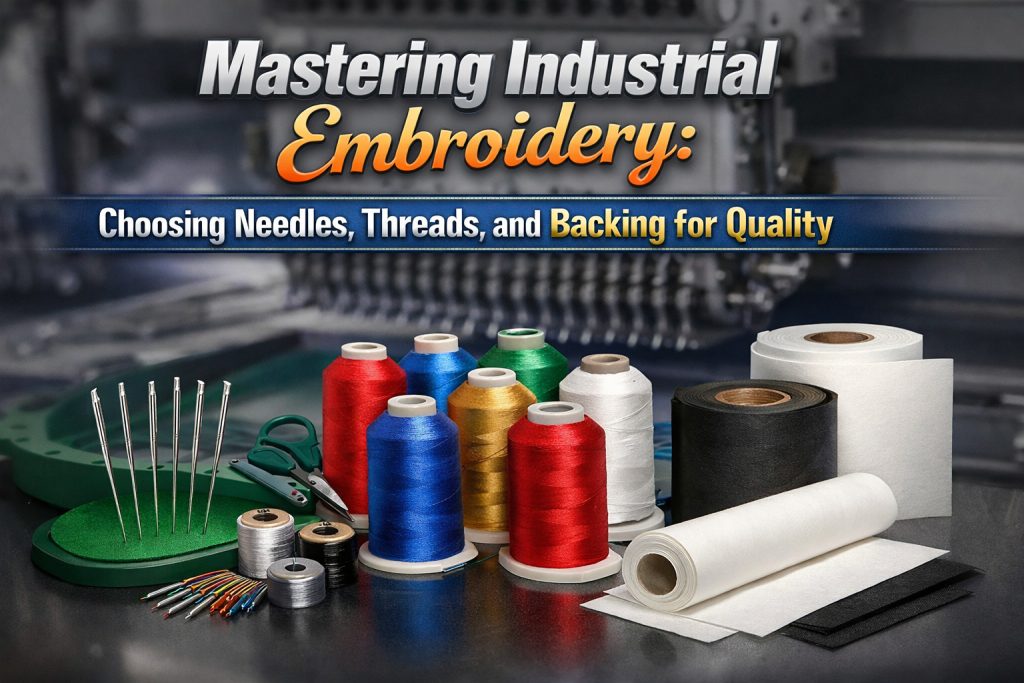

In the competitive world of garment manufacturing, value addition is paramount for enhancing product appeal and securing better margins. Industrial embroidery is a prime example of such value addition, transforming basic fabrics into distinctive, high-value items. However, achieving consistently high-quality embroidery is not solely about the machine; it fundamentally depends on the intelligent selection and combination of consumables: needles, threads, and backing materials. The machine shown above is installed in a modern garment factory, where precise material selection contributes significantly to the output quality and operational efficiency. The setup in the image illustrates how a well-maintained industrial embroidery solution fits into a value-addition line, capable of producing intricate designs on various textiles.

At DukeJia, represented in India by Hari Chand Anand & Co. (HCA), we understand that the backbone of superior embroidery lies in this synergy. As your value-addition machinery partner, supplying and servicing advanced industrial embroidery, perforation, and quilting machines across India (including Delhi NCR, Tirupur, Ludhiana, Chennai, Bengaluru), we emphasize that optimizing your consumables is as critical as your machine’s capabilities.

Understanding the Embroidery Ecosystem: Needles, Threads, and Backing

To truly master industrial embroidery, garment factories – from production managers to maintenance teams – must grasp the individual roles and collective impact of these three critical components.

1. The Right Needle for the Fabric

The needle is the first point of contact between your machine and the fabric. Its selection directly impacts fabric integrity, stitch quality, and machine performance.

Needle Types & Sizes:

- Sharp Point (R or RG): Ideal for woven fabrics like denim, canvas, twill, and uniforms. It pierces tightly woven structures cleanly.

- Ballpoint (SES or SUK): Essential for knitwear, T-shirts, polos, and sportswear. Its rounded tip pushes fabric fibers aside rather than cutting them, preventing holes, snags, and runs.

- Titanium-Coated: Offers enhanced durability and reduced friction, extending needle life, especially for dense designs or abrasive materials.

- Sizes: Needles are graded by size (e.g., 65/9, 75/11, 80/12, 90/14). A finer needle (smaller number) is for lighter fabrics and finer threads, while a thicker needle (larger number) is for heavier fabrics and coarser threads. Using too fine a needle for heavy fabric causes breakage; too thick a needle on delicate fabric can leave visible holes.

Impact on Production:

Incorrect needle choice leads to frequent thread breaks, fabric damage (holes, snags, puckering), skipped stitches, and overall poor embroidery quality. Regular replacement (every 8-10 production hours or after specific design counts) is crucial, as even a slightly bent or dull needle can cause significant issues.

2. Selecting the Optimal Thread

Thread defines the visual and tactile quality of your embroidery. Its type, material, and count profoundly influence durability, appearance, and machine efficiency.

Thread Materials:

- Polyester: Highly durable, colorfast, and resistant to bleaching, making it excellent for uniforms, activewear, children’s clothing, and home textiles that undergo frequent washing. Offers a good sheen.

- Rayon: Known for its brilliant luster and soft hand-feel, often preferred for fashion garments, logos, and intricate designs where aesthetics are paramount. Less durable than polyester but vibrant.

- Metallic: Used for specialty designs requiring sparkle and high visual impact. Requires careful handling, specific needles, and often slower machine speeds to prevent breakage.

- Cotton: Offers a matte finish and natural feel, suitable for organic or vintage-look garments. Less strong than synthetics.

Thread Count (Denier/Tex):

Refers to the thread’s thickness. Common counts for industrial embroidery include 40wt (standard), 30wt (thicker, for bolder lines), and 60wt (finer, for detailed work). Matching thread count to needle size and fabric weight is critical for balanced tension and consistent stitch formation.

Impact on Production:

Low-quality thread can lead to excessive lint, frequent thread breaks, inconsistent tension, and faded designs after washing. High-quality threads ensure smooth running, fewer stoppages, and long-lasting, vibrant embroidery, directly affecting garments like T-shirts, jackets, and sportswear.

3. The Crucial Role of Backing (Stabilizers)

Backing material provides the necessary stability to the fabric during the embroidery process, preventing puckering, stretching, and distortion. It’s the unseen hero of quality embroidery.

Types of Backing:

- Cut-Away: Provides permanent stability, preventing distortion over time, especially for unstable fabrics like knits (polos, T-shirts, sweatshirts) or dense designs. It remains with the embroidery after trimming.

- Tear-Away: Offers temporary stability and is easily removed after embroidery. Ideal for stable woven fabrics (caps, bags, woven shirts, home textiles) where a soft hand-feel is desired on the back.

- Wash-Away/Water-Soluble: Dissolves completely in water, leaving no trace. Used when no backing should remain, such as on delicate lace or sheer fabrics.

- Heat-Away: Removes with heat, suitable for fabrics that cannot be wet or where a clean finish is paramount without moisture.

Weight/Ply:

Backings come in various weights (light, medium, heavy) and plies (single, double). The choice depends on fabric stability, stitch density, and design complexity. A heavy backing for a dense design on a knit fabric ensures stability and prevents puckering.

Impact on Production:

Inadequate backing leads to puckering, poor registration, fabric shifting, and compromised design integrity. Correct backing ensures smooth embroidery, crisp designs, and a professional finish, crucial for items like uniforms, logos, and appliqué work.

Where and Why These Choices Matter: A Garment Factory’s Perspective

The deliberate selection of needles, threads, and backing directly addresses numerous challenges on the shop floor and significantly boosts profitability.

Applications:

These principles apply universally across all embroidered products: logos on T-shirts and polos, intricate designs on knitwear, robust emblems on jackets and uniforms, decorative elements on home textiles, and branding on sportswear.

Problems Solved:

- Minimizes fabric damage (holes, runs, snags).

- Reduces thread breaks and machine downtime.

- Eliminates puckering, distortion, and poor stitch registration.

- Ensures consistent, high-quality output across batches.

Impact on Quality & Efficiency:

- Quality: Delivers sharp, clean, and durable embroidery with the desired aesthetic (sheen, matte, texture) and hand-feel.

- Speed: Fewer thread breaks and less re-hooping mean higher machine uptime and faster production cycles. Industrial embroidery machines (like those from DukeJia) operate efficiently, and optimized consumables ensure they maintain peak performance.

- Operator Comfort: Reduced troubleshooting for issues like thread breaks or skipped stitches, allowing operators to manage more machines or focus on critical tasks.

- Power Consumption & Running Cost: Efficient production with minimal re-runs and material waste reduces overall operational costs. Proper consumables also extend the life of machine parts (e.g., hooks, needles).

- Value-Addition & FOB/Margin: High-quality, consistent embroidery elevates the perceived value of the garment, allowing factories to command higher FOB (Free On Board) prices and achieve better profit margins. Unique, flawless designs are a key differentiator in a crowded market.

Technical Aspects of Industrial Embroidery

Modern industrial embroidery machines, such as those supplied by DukeJia, are sophisticated systems designed for high-volume, precise work.

Working Principle:

Multi-head computerized embroidery machines operate by moving a fabric frame (pantograph) under multiple stationary needle heads. Each head performs synchronized stitching according to a pre-programmed digital design file (e.g., DST format). The main shaft drives the needle bar, while the rotary hook (or oscillating shuttle) creates the lock stitch.

Key Components:

- Needle Bar Assembly: Holds the needle, moving it up and down.

- Rotary Hook/Bobbin Case: Catches the needle thread loop and intertwines it with the bobbin thread to form a lock stitch.

- Tension Discs: Control the tension of the upper thread, crucial for balanced stitch formation.

- Presser Foot: Holds the fabric securely during stitching.

- Pantograph/Frame Drive: Moves the hoop/frame in X and Y directions, positioning the fabric for each stitch.

Stitch Formation:

The needle descends, piercing the fabric and carrying the upper thread. As it retracts, it forms a loop. The rotary hook spins, catches this loop, and carries it around the bobbin case. The bobbin thread is pulled through this loop, creating an interlocking “lock stitch” before the needle descends again.

Production Capacities:

Depending on the design complexity, number of stitches, and machine configuration (e.g., 12-head, 15-needle machines), industrial embroiderers can achieve speeds typically ranging from 700 to 1200 stitches per minute. For example, a multi-head machine can produce hundreds of logos per hour.

Maintenance & Daily Care:

- Needles: Inspect and replace regularly.

- Thread Path: Clean thread guides, tension discs, and take-up levers daily to remove lint and dust.

- Oiling: Follow manufacturer guidelines (e.g., DukeJia recommendations) for regular oiling of hooks, needle bars, and other moving parts.

- Tension Checks: Calibrate upper and bobbin thread tension for each design and fabric change.

- Cleaning: Remove lint and debris from under the needle plate and around the hook area.

- Preventive Maintenance: Scheduled checks and service by experts like HCA’s technicians ensure optimal machine performance and longevity.

The True Cost of Consumables: Initial Price vs. Operational Efficiency

When choosing consumables, factories often face a dilemma: invest in premium quality or opt for budget-friendly alternatives. Understanding the long-term impact is key.

| Feature | Budget Consumables | Premium Consumables (e.g., from Reputable Brands) |

|---|---|---|

| Initial Cost | Lower | Higher |

| Thread Breakage | Frequent, leading to significant downtime | Infrequent, ensuring continuous production |

| Embroidery Quality | Inconsistent, prone to puckering, skipped stitches | Crisp, consistent, vibrant, professional finish |

| Fabric Damage | Higher risk (dull needles, poor thread) | Minimal risk (optimized needles, smooth thread) |

| Machine Wear | Increased wear on tension discs, needle bars, hooks | Reduced wear, extending machine lifespan |

| Operator Intervention | High (re-threading, troubleshooting) | Low, improving operator comfort and efficiency |

| Rework/Waste | Significant material waste and rework | Minimal waste, higher first-pass quality |

| Overall Output | Lower due to stops, quality issues | Higher, consistent, reliable output |

| Product Value | Limited value-add, potential rejection | Enhanced value, better FOB, stronger brand image |

While premium consumables might have a higher upfront cost, they lead to substantial savings in reduced downtime, less rework, lower material waste, and extended machine life. More importantly, they guarantee consistent, high-quality embroidery, which directly translates to a stronger market position and higher profit margins for products ranging from apparel to home textiles.

Troubleshooting Common Embroidery Issues

Even with the best machines and consumables, issues can arise. Here are common problems and their likely solutions:

| Problem | Likely Causes | Basic Solutions |

|---|---|---|

| Skipped Stitches | Wrong needle type/size, dull needle, incorrect timing | Replace needle (correct type/size), check machine timing (HCA service) |

| Frequent Thread Breaks | Poor quality thread, incorrect tension (too high), burrs on needle/machine parts, wrong needle size, machine timing | Use quality thread, adjust tensions, inspect/replace needle, clean thread path, service machine for timing issues |

| Puckering/Distortion | Insufficient backing, incorrect hooping tension, too dense a design for fabric, dull needle | Use heavier/correct backing, re-hoop properly (not too tight), adjust design density, replace needle |

| Looped Stitches (Top) | Bobbin tension too tight, upper thread tension too loose, poor thread seating | Adjust bobbin tension, increase upper thread tension, re-thread upper path correctly |

| Looped Stitches (Bottom) | Upper thread tension too tight, bobbin tension too loose | Decrease upper thread tension, adjust bobbin tension, clean bobbin case |

| Fabric Damage (Holes/Snags) | Wrong needle type (sharp on knit), dull/bent needle, high stitch density | Use ballpoint needle for knits, replace needle, adjust design parameters |

For persistent or complex issues, always consult your machine service provider like Hari Chand Anand & Co. (HCA) for expert diagnosis and repair.

Selection Checklist for Garment Factories

Before starting any embroidery project, consider these factors:

1. Fabric Assessment:

- Type: Woven, knit, delicate, heavy?

- Weight/Stability: How much stretch or give does it have?

- Application: Will it be washed frequently, worn close to the skin?

2. Design Complexity:

- Stitch Count: Low, medium, high?

- Density: Are there large fill areas or fine details?

- Size: Small logo or large appliqué?

3. Desired Outcome:

- Hand-feel: Soft, firm, crisp?

- Durability: Must withstand industrial washing, abrasion?

- Aesthetics: High sheen, matte finish, specific texture?

4. Machine Capabilities:

- Is your machine calibrated and well-maintained?

- Are you using appropriate hoops for the garment/design?

5. Consumable Sourcing:

- Are your suppliers reliable for consistent quality?

- Do they offer technical support and guidance on optimal choices?

Key Takeaways

- The quality of embroidery is a direct result of matching the correct needle, thread, and backing to the fabric and design.

- This careful selection significantly impacts production efficiency, reducing downtime and waste.

- Investing in quality consumables ensures superior aesthetics, durability, and a comfortable hand-feel for the final product.

- Correct maintenance and troubleshooting are essential for maximizing machine performance and longevity.

- Ultimately, informed consumable choices enhance product value, allowing factories to secure better FOBs and margins.

DukeJia, through Hari Chand Anand & Co. (HCA), is committed to being your partner in achieving excellence in value-addition. We supply and service industrial embroidery, perforation, and quilting systems, providing not just machines but also comprehensive after-sales support including installation, operator training, preventive maintenance schedules, genuine spare parts, and responsive on-call service teams. Whether you’re producing precise logos, all-over quilting, sportswear perforation, or intricate appliqué designs, our expertise extends beyond machinery to the entire production ecosystem.

Frequently Asked Questions

Why is needle selection so critical in industrial embroidery?

The needle is the first point of contact with the fabric, and the right choice prevents fabric damage (holes, snags), reduces thread breaks, ensures proper stitch formation, and maintains overall machine performance and product quality. Using the wrong needle can lead to significant production issues and waste.

What is the main difference between polyester and rayon embroidery threads?

Polyester thread is highly durable, colorfast, and resistant to frequent washing and bleaching, making it ideal for uniforms and activewear. Rayon thread, while less durable, offers a brilliant luster and soft hand-feel, often preferred for fashion garments and intricate designs where aesthetics are paramount.

When should I use a cut-away backing versus a tear-away backing?

Cut-away backing provides permanent stability and is best for unstable fabrics like knits (T-shirts, polos) or dense designs where long-term distortion prevention is needed. Tear-away backing offers temporary stability and is easily removed, making it suitable for stable woven fabrics (caps, bags) where a soft feel on the back is desired.

How does DukeJia / HCA support customers beyond selling machines?

DukeJia, through Hari Chand Anand & Co. (HCA), provides comprehensive after-sales support including installation, operator training, preventive maintenance schedules, genuine spare parts, and responsive on-call service teams. Our expertise covers the entire production ecosystem, ensuring optimal machine performance and longevity.

What impact do quality consumables have on a garment factory’s profitability?

Investing in quality consumables significantly reduces downtime from thread breaks and re-hooping, minimizes material waste from reworks, and extends machine lifespan. This efficiency leads to higher, more consistent output and superior embroidery quality, allowing factories to command better FOB prices and achieve higher profit margins.

What are common causes for puckering in embroidery and how can it be prevented?

Puckering is often caused by insufficient backing, incorrect hooping tension (too tight or loose), or a design that is too dense for the fabric. It can be prevented by using the correct weight and type of backing, hooping the fabric properly without excessive stretching, and optimizing design density for the chosen textile.

For DukeJia embroidery, perforation or quilting machine demonstrations, pricing or technical consultation, contact Hari Chand Anand & Co. (HCA), New Delhi.