Published on: 30 Jan 2026

Planning Garment Production with Embroidery & Quilting: DukeJia & HCA

Key takeaways for garment factories:

- Strategic planning for embroidery and quilting integration is vital for optimizing garment production workflows and enhancing product value.

- Modern industrial embroidery and quilting machines significantly boost quality, speed, and reduce operational costs through precision and automation.

- Higher levels of automation in machinery are crucial for achieving production scale, ensuring consistent quality, and reducing dependency on highly skilled manual labor.

- Diligent maintenance and daily care practices are essential for maximizing machine longevity, ensuring consistent performance, and minimizing downtime.

- DukeJia, represented by HCA, offers comprehensive, reliable machinery solutions and unparalleled after-sales support tailored for the Indian garment manufacturing sector.

Table of Contents

- Planning Garment Production with Embroidery and Quilting

- The Role of Industrial Embroidery in Modern Garment Production

- Integrating Industrial Quilting for Specialized Products

- Addressing Shop Floor Challenges with Modern Machinery

- Machine Selection: Automation and Origin Comparison

- Essential Maintenance and Daily Care for Longevity

- Troubleshooting Common Issues

- Selecting the Right Machine: A Buyer’s Checklist

- DukeJia & HCA: Your Partner in Value Addition

- Frequently Asked Questions

The modern garment industry thrives on efficiency, quality, and distinctive value-added features. For factories aiming to elevate their product offerings and secure better margins, the strategic integration of specialized processes like embroidery and quilting is paramount. This requires meticulous planning garment production with embroidery and quilting to optimize workflows, minimize costs, and maximize output.

Planning Garment Production with Embroidery and Quilting

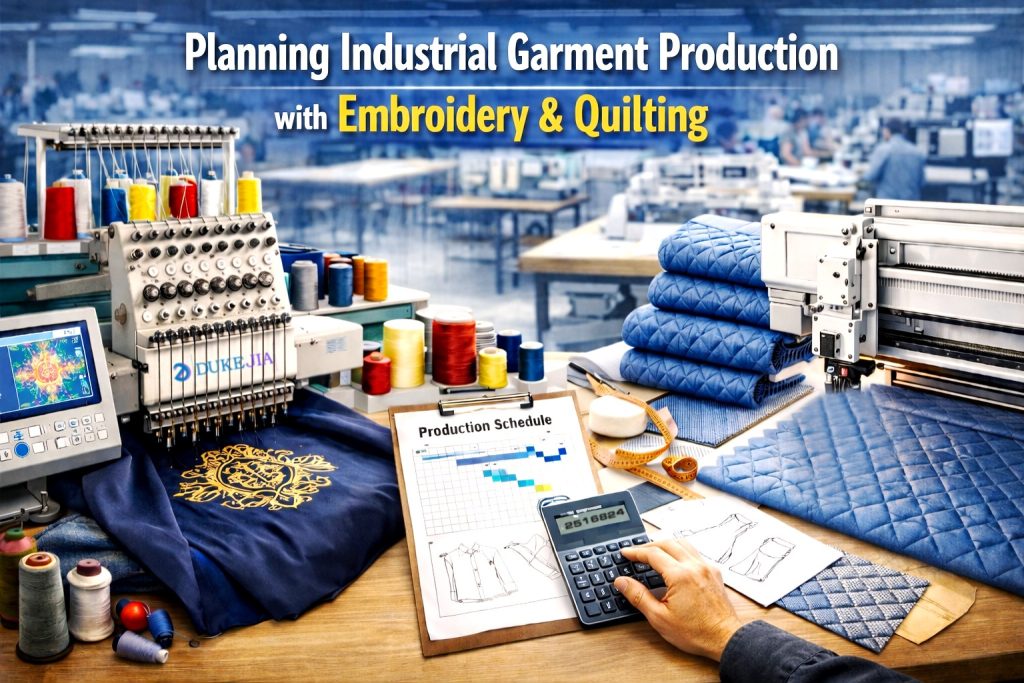

The setup in the image illustrates how a modern industrial machine integrates seamlessly into a value-addition line, demonstrating the precision and scale achievable with advanced technology. Such equipment is central to strategically planning garment production, ensuring that processes like embroidery and quilting enhance, rather than hinder, overall efficiency. DukeJia, represented in India by Hari Chand Anand & Co. (HCA), understands this critical balance, supplying and servicing industrial embroidery, perforation, and quilting machines that empower garment factories across India.

The Role of Industrial Embroidery in Modern Garment Production

Industrial embroidery machines are workhorses for adding branding, decorative elements, and intricate designs to a wide range of garments.

Applications:

From corporate logos on uniforms and polo shirts to decorative patterns on t-shirts, knitwear, caps, and sportswear, embroidery elevates perceived value and brand identity. Appliqué and specialized thread work further expand design possibilities.

Working Principle & Key Components:

Modern multi-head embroidery machines operate on digitized patterns. Each head typically functions independently, applying stitches simultaneously. The core mechanism involves a needle moving vertically to create the stitch, while a rotary hook or bobbin system catches the thread from below, forming a lockstitch. The fabric, held in a tensioned hoop, is moved precisely by X-Y servo motors according to the digitized design. Key components include:

- Needle Bars: Holding needles that pierce the fabric.

- Rotary Hooks: Grasping the needle thread to form loops with the bobbin thread.

- Thread Tensioners: Ensuring consistent thread flow for optimal stitch quality.

- Frame Driving Motors: Precisely controlling the movement of the embroidery frame.

- Control Panel: User interface for pattern selection, parameter adjustment, and machine operation.

- Automatic Thread Trimming: Sensors detect thread breaks and trim excess threads between design elements, enhancing efficiency.

Production Planning Considerations:

Integrating embroidery requires factoring in:

- Digitization Time: Converting artwork into machine-readable embroidery files.

- Multi-head Efficiency: Maximizing simultaneous production across multiple heads.

- Color Changes: Planning the sequence of thread colors to minimize stoppages.

- Capacity: Typical speeds range from 600 to 1200 stitches per minute (SPM) per head, though this varies with design complexity.

Benefits:

- Quality: Unmatched precision and repeatability for complex designs.

- Speed: High-volume output due to multi-head functionality.

- Operator Comfort: Reduced manual intervention, automatic thread changes and trimming.

- Running Cost: Efficient thread usage, minimal defects reduce material waste.

- Value-addition: Creates a premium, durable finish, enabling higher FOB (Free On Board) prices.

Integrating Industrial Quilting for Specialized Products

Industrial quilting machines are indispensable for products requiring insulation, padding, or distinctive surface textures.

Applications:

Essential for jackets, padded garments, home textiles (quilts, bedspreads), mattress panels, and even automotive interiors.

Working Principle & Key Components:

Multi-needle quilting machines typically work with multiple layers of fabric and batting. Needles move in unison, stitching patterns across the material as it feeds through the machine. Computerized systems allow for a vast array of intricate, continuous patterns. Key components include:

- Needle Bar: Holding multiple needles across the width of the machine.

- Presser Foot/Roller System: Keeping the fabric layers stable during stitching.

- Fabric Feeding System: Automated rollers ensure smooth and consistent material movement.

- Pattern Recognition/CAD Integration: Allows for loading and executing complex, continuous quilting patterns.

- Tensioning Systems: Crucial for maintaining consistent stitch quality across all needles.

Production Planning Considerations:

- Material Handling: Managing large rolls of fabric and batting efficiently.

- Pattern Complexity vs. Speed: Simpler linear patterns are faster than intricate designs.

- Material Compatibility: Ensuring fabric, batting, and thread work together for desired loft and drape.

- Capacity: Ranges from 50 to 200 meters per hour, depending on pattern density and machine specifications.

Benefits:

- Quality: Uniform stitch, consistent loft, and even distribution of insulation.

- Speed: High continuous output, especially with wide-width machines.

- Operator Comfort: Automated feeding reduces manual effort and fatigue.

- Running Cost: Optimized material usage, reduced rework.

- Value-addition: Enhances aesthetics, provides insulation, and confers a premium, finished look.

Addressing Shop Floor Challenges with Modern Machinery

Modern industrial embroidery and quilting machines directly address several common shop floor challenges:

- Consistency Issues: Computerized precision eliminates manual errors, ensuring identical output across batches.

- Production Bottlenecks: Multi-head embroidery and multi-needle quilting dramatically increase throughput, preventing delays.

- Skilled Labor Dependency: Automation reduces the need for highly specialized manual skills, making operation more accessible.

- Downtime: Robust designs and user-friendly interfaces with diagnostic capabilities facilitate quick issue resolution and preventive maintenance, minimizing stoppages.

Machine Selection: Automation and Origin Comparison

Choosing the right machine involves evaluating technology and origin against specific production needs.

| Feature | Mechanical/Semi-Mechanical Machines | Fully Computer-Controlled Machines |

|---|---|---|

| Initial Cost | Lower | Higher |

| Flexibility | Limited patterns, often fixed for mechanical quilting | Infinite pattern possibilities, easy pattern changes |

| Speed/Accuracy | Slower, precision dependent on operator skill | Faster, high precision, repeatable |

| Operator Skill | Higher manual skill required | Easier operation, pattern loading via software |

| Integration | Standalone | Integrates with CAD/CAM systems, network-capable |

| Ideal For | Niche, very basic needs, extremely low volume | High volume, diverse designs, consistent quality |

Automation Levels (Basic vs. Multi-head/Advanced):

- Basic Models: A single-head embroidery machine or a simple linear quilting machine might suffice for sampling, very small custom orders, or niche production requiring minimal pattern variation.

- Higher Automation (Multi-head, Automatic Trimming, Pattern Memory): Justified for factories engaged in mass production, diverse product lines, and requiring rapid turnaround times. Features like automatic thread trimming, color change, and large pattern memory significantly boost productivity and consistency.

Japanese/European vs. Chinese/Other Asian Machines:

- Japanese/European Machines: Renowned for superior build quality, precision, longer lifespan, and often advanced technological features. They come with a higher initial investment but offer excellent long-term reliability and precise engineering. After-sales support is typically very strong, though parts can be more expensive.

- Chinese/Other Asian Machines: Offer a compelling balance of cost-effectiveness and features. Quality has significantly improved, providing reliable performance at a more accessible price point. Spares are generally more readily available and affordable. DukeJia machines, supplied by HCA, represent this segment, providing a balance of advanced technology, robust construction, and competitive pricing backed by strong local support.

Essential Maintenance and Daily Care for Longevity

Proper maintenance extends machine life and ensures consistent quality.

- Needles: Use the correct needle type and size for the fabric and thread. Replace needles regularly (e.g., every 8-10 hours of operation) to prevent skipped stitches and thread breaks.

- Thread Path: Ensure the thread path is clear, clean, and free from obstructions. Correct tension settings are crucial for balanced stitches.

- Cleaning: Daily cleaning of dust, lint, and thread residue from the needle bar, rotary hook area, and bobbin case is essential.

- Oiling: Follow the manufacturer’s guidelines for oiling specific moving parts. This lubricates components and reduces wear.

- Calibration: Periodically check and adjust thread tensions, and ensure timing between the needle and hook is accurate. Professional technicians from HCA can assist with detailed calibration during preventive maintenance visits.

- Daily Checks: Briefly inspect machine stability, electrical connections, and sensor functions before starting operations.

Troubleshooting Common Issues

| Issue | Likely Causes | Basic Solutions |

|---|---|---|

| Embroidery: Thread Breaks | Incorrect thread tension, worn/bent needle, burr on hook, poor thread quality, incorrect hooping | Adjust tension, change needle, clean/inspect hook, use quality thread, re-hoop fabric correctly |

| Embroidery: Poor Stitch Quality / Looping | Incorrect tension (top or bobbin), blunt needle, fabric too loose in hoop | Adjust tensions, change needle, ensure fabric is tautly hooped |

| Quilting: Irregular Stitch Length | Fabric feeding issue (slippage), worn drive belt, tension imbalance | Check fabric feed system, inspect/replace drive belts, adjust tensions evenly |

| Quilting: Puckering / Material Shifting | Incorrect tension settings, improper layering of materials, feed timing issue | Adjust top and bobbin tensions, ensure material layers are flat and aligned, consult service for timing |

Selecting the Right Machine: A Buyer’s Checklist

When investing in industrial embroidery or quilting machinery, consider:

- Production Volume & Product Type: Match machine capacity and features to your current and projected output and specific garment types.

- Desired Automation Level: Evaluate if basic, semi-automatic, or fully automated systems are most cost-effective for your operations.

- Budget: Balance initial investment with long-term running costs, including power consumption and spare parts availability.

- Technical Support & Spares: Ensure reliable after-sales service, installation, training, and ready availability of genuine spare parts (a key strength of DukeJia/HCA).

- Operator Training: Assess the ease of operation and training requirements for your workforce.

- Integration Needs: Consider compatibility with existing CAD systems or other production lines.

- Specific Features: Look for attributes like large embroidery areas, specific quilting patterns, or laser perforation capabilities (offered by DukeJia).

DukeJia & HCA: Your Partner in Value Addition

DukeJia, through Hari Chand Anand & Co. (HCA), is committed to being a comprehensive value-addition machinery partner for garment factories. We supply and service state-of-the-art industrial embroidery, perforation, and quilting systems designed for the Indian market. Our solutions enable precise logo and placement embroidery, all-over quilting for diverse textile products, sportswear perforation for enhanced functionality and design details, and creative appliqué work. Our after-sales support is a cornerstone of our commitment, including professional installation, thorough operator training, preventive maintenance programs, ready availability of genuine spares, and responsive on-call service teams strategically located across major garment manufacturing hubs like Delhi NCR, Tirupur, Ludhiana, Chennai, and Bengaluru.

Frequently Asked Questions

What are the primary benefits of integrating industrial embroidery into garment production?

Industrial embroidery enhances garment value by adding branding, intricate decorative elements, and durable designs. It offers unmatched precision, high-volume output through multi-head functionality, reduces manual intervention, and enables higher selling prices (FOB) due to the premium finish.

How do modern quilting machines contribute to efficiency in textile manufacturing?

Modern multi-needle quilting machines provide high continuous output with uniform stitch quality and consistent loft, essential for padded garments and home textiles. Automated feeding systems reduce labor, minimize material waste, and allow for a vast array of intricate patterns, significantly boosting production efficiency and product aesthetics.

What is the typical lifespan for industrial embroidery or quilting machines, and how can it be maximized?

With proper maintenance, industrial machines can last 10-15 years or more. Maximizing longevity requires daily cleaning, regular oiling as per manufacturer guidelines, timely needle replacement, correct thread path management, periodic calibration by professional technicians, and adherence to preventive maintenance schedules.

Should a garment factory invest in Japanese/European or Chinese/Other Asian machines?

Japanese/European machines offer superior build quality, precision, and longer lifespan at a higher initial cost. Chinese/Other Asian machines, like DukeJia, provide a competitive balance of cost-effectiveness, advanced features, and reliable performance, with readily available and affordable spares. The choice depends on budget, required precision, long-term operational costs, and access to after-sales support.

What kind of after-sales support does DukeJia / HCA offer for their machinery?

DukeJia, through HCA, provides comprehensive after-sales support including professional installation, thorough operator training, preventive maintenance programs, ready availability of genuine spare parts, and responsive on-call service teams located across major garment manufacturing hubs in India.

For DukeJia embroidery, perforation or quilting machine demonstrations, pricing or technical consultation, contact Hari Chand Anand & Co. (HCA), New Delhi.